Types of Concrete Cracks

Concrete is a durable and versatile building material, but like any material, it is not immune to wear and tear. One of the most common issues faced by concrete structures is cracking. Understanding the different types of concrete cracks and their causes is essential for effective prevention and repair. Let’s dive into the various types of concrete cracking and explore ways to manage them.

Table of Contents

Causes of Concrete Cracks

Concrete cracks can occur for several reasons. Environmental factors such as extreme temperatures, moisture levels, and natural disasters can lead to cracking. Additionally, material quality plays a significant role. Poorly mixed concrete, low-quality materials, or improper ratios of ingredients can weaken the structure. Finally, construction techniques are critical. Poor workmanship, inadequate curing, or incorrect placement can all lead to cracks in the concrete.

Types of Concrete Cracks

1. Plastic Shrinkage Cracks

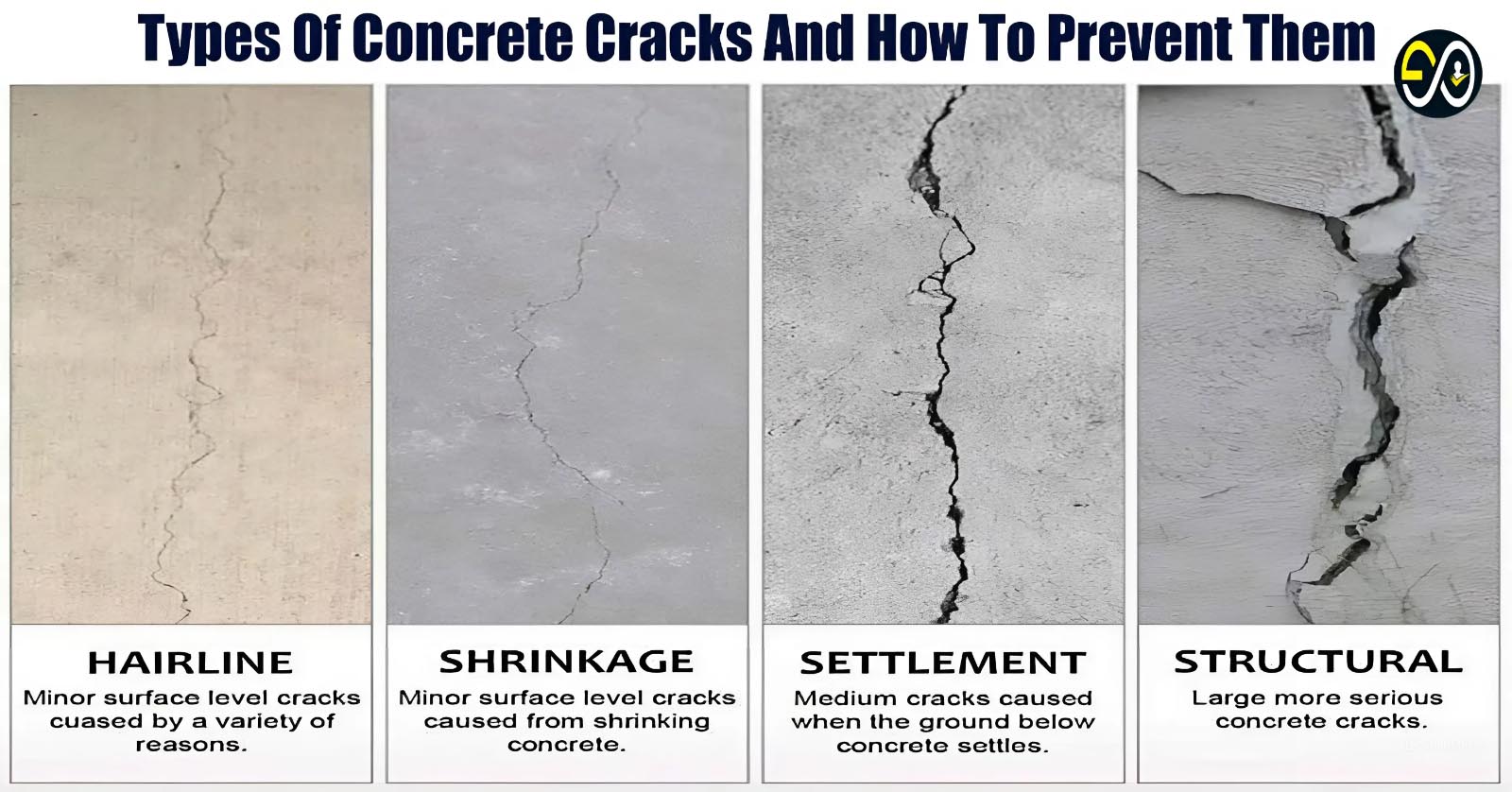

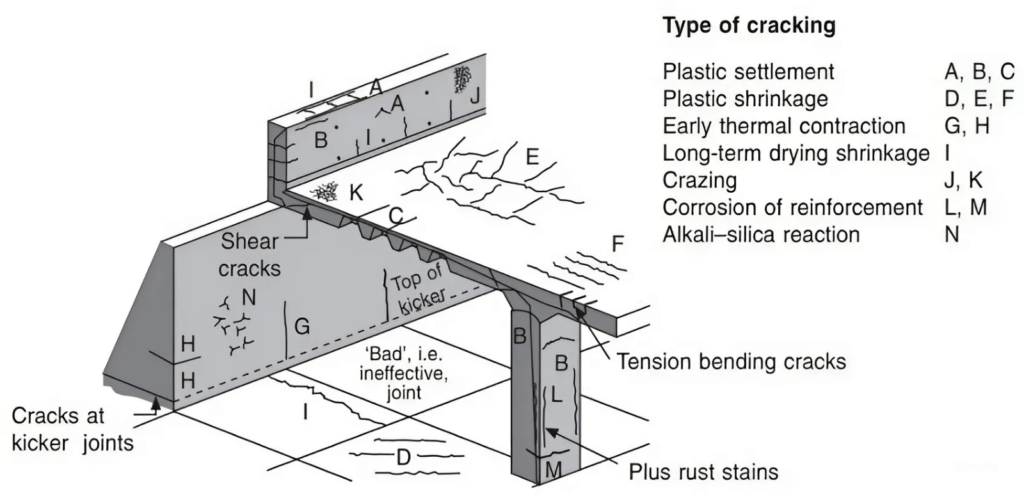

Plastic shrinkage cracks are shallow, irregular cracks that occur when the concrete is still in its plastic state. These cracks are often a result of the concrete drying too quickly. If the surface of the concrete loses moisture faster than the concrete’s interior, tension builds up, leading to cracks.

Prevention: To prevent plastic shrinkage cracks, it’s essential to keep the surface moist during the curing process. This can be achieved by covering the concrete with plastic sheeting or using a curing compound.

2. Drying Shrinkage Cracks

Drying shrinkage cracks appear as hairline cracks that run parallel to each other. These cracks occur as the concrete dries and shrinks over time. Drying shrinkage is a natural process in concrete, but if the shrinkage is excessive, it can lead to cracking.

Prevention: To minimize drying shrinkage cracks, ensure proper curing methods and use low-shrinkage concrete mixtures. Adding reinforcement can also help distribute the stress and reduce the chances of cracking.

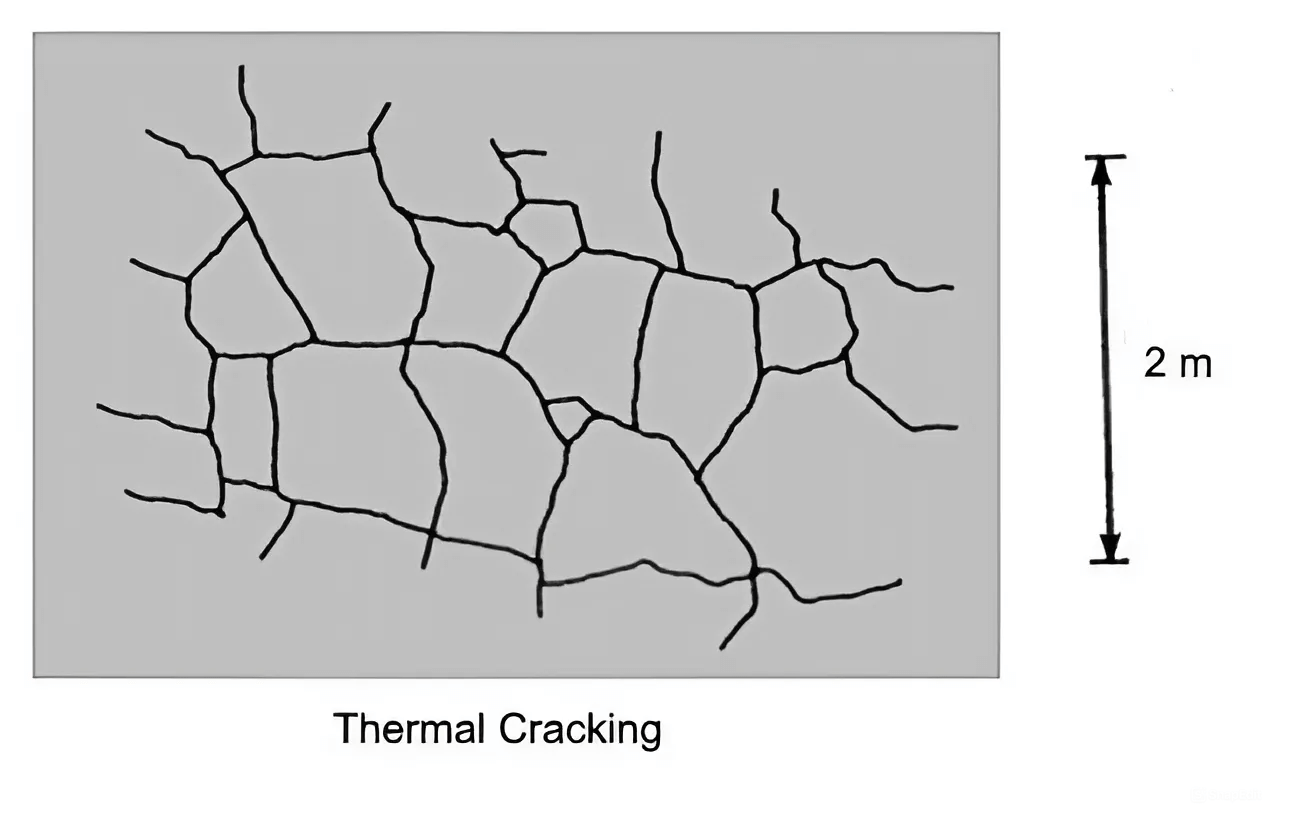

3. Thermal Cracks

Thermal cracks are caused by temperature changes in the concrete. Concrete expands when exposed to heat and contracts when cooled. If these temperature changes are extreme, the resulting stress can cause the concrete to crack.

Prevention: Proper insulation and controlled temperature changes during the curing process can help prevent thermal cracking. Additionally, designing expansion joints can accommodate temperature-related movements and reduce the risk of cracking.

4. Settlement Cracking

Settlement cracking occurs when the soil beneath the concrete settles or shifts, causing the concrete to crack and become uneven. This type of cracking is often seen in driveways, sidewalks, and foundations.

Prevention: To prevent settlement cracking, it’s important to ensure that the soil is properly compacted before pouring the concrete. Additionally, using a strong foundation and reinforcing the concrete can help reduce the risk of settlement cracking.

5. Structural Cracks

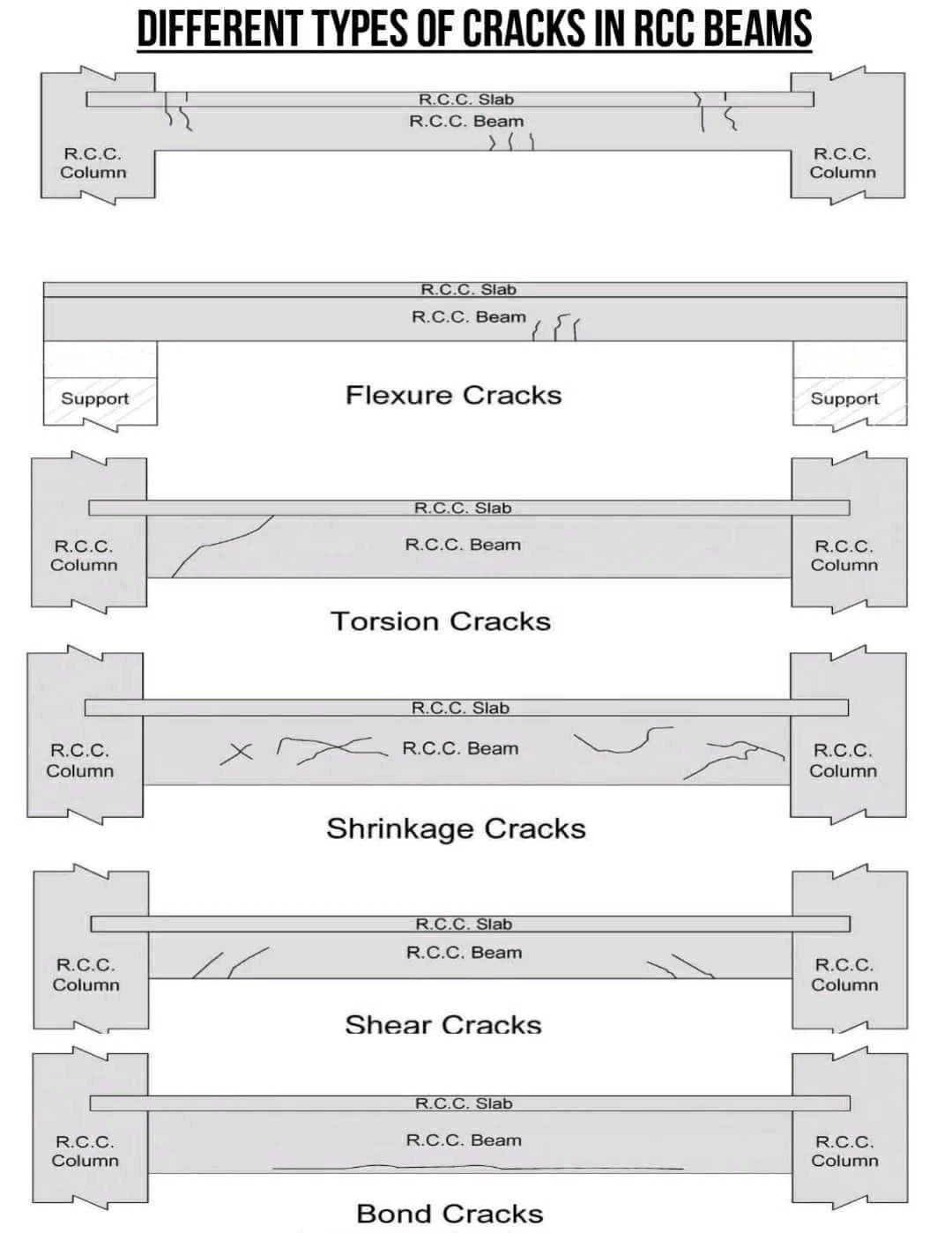

Structural cracks are caused by overloading, inadequate design, poor materials, or poor construction. These cracks can compromise the integrity of the structure and may widen over time. Structural cracks can be categorized into different types:

- Shear Cracks: These cracks occur due to shear stress, often seen in beams and columns.

- Flexural Cracks: These cracks are caused by the bending or flexing of the concrete.

- Shear/Flexural Cracks: A combination of shear and flexural stresses can lead to these cracks.

- Torsion Cracks: Twisting forces can cause torsion cracks, typically seen in beams subjected to uneven loading.

Prevention: Proper design, high-quality materials, and accurate construction techniques are essential in preventing structural cracks. Regular inspections can also help identify potential issues before they escalate.

6. Corrosion Cracks

Corrosion cracks occur when the reinforcement steel inside the concrete begins to corrode. As the steel corrodes, it expands, creating internal pressure that leads to cracking.

Prevention: Using corrosion-resistant materials, ensuring proper concrete cover over reinforcement, and applying protective coatings can help prevent corrosion cracks. Additionally, controlling moisture exposure can reduce the risk of corrosion.

7. Cracks Due to Alkali-Aggregate Reaction (AAR)

Alkali-aggregate reaction (AAR) is a chemical reaction between the alkaline cement paste and certain types of aggregates in the concrete. This reaction produces a gel-like substance that can expand and cause cracks over time. There are two main types of AAR:

- Alkali-Silica Reaction (ASR): This occurs when silica in the aggregate reacts with alkalis in the cement paste, leading to expansion and cracking.

- Alkali-Carbonate Reaction (ACR): This reaction occurs between certain carbonate aggregates and alkalis in the cement, also resulting in expansion and cracking.

Prevention: To prevent AAR, use low-alkali cement and select less reactive aggregates. Regular monitoring and maintenance can help detect early signs of AAR and mitigate its effects.

Recognizing Cracks Early

Early detection of cracks is crucial for preventing further damage. Common signs of different crack types include visible lines, uneven surfaces, and discoloration. Regular inspections can help identify these signs before the cracks worsen.

Assessing the Severity of Cracks

Not all cracks are created equal. Some are purely cosmetic, while others can indicate serious structural issues. Determining the severity of cracks involves assessing their width, length, and location. If you’re unsure, it’s always best to seek professional help.

Repair Techniques for Concrete Cracks

There are several methods to repair concrete cracks, depending on their type and severity:

- Epoxy Injection: This method is used for filling and sealing cracks, and restoring the structural integrity of the concrete.

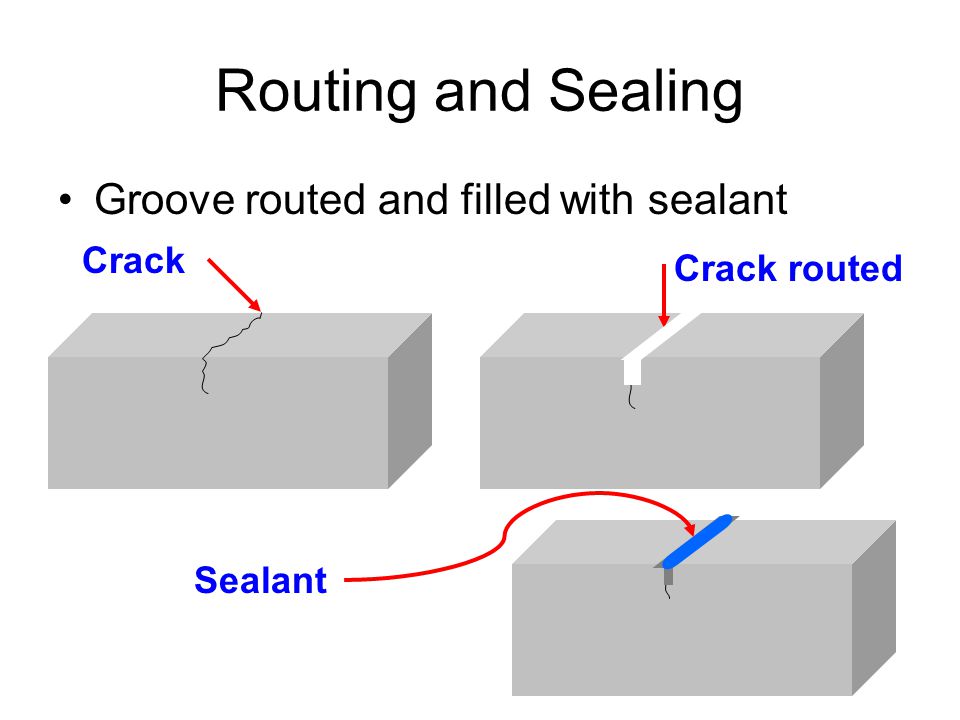

- Routing and Sealing: This involves enlarging the crack and filling it with a flexible sealant.

- Stitching: Steel bars are inserted across the crack to hold the concrete together.