When working on construction projects, knowing the weight of the I-beam or H-beam sections is crucial. These beams form the backbone of many structural frameworks, and their weight impacts not only the load-bearing capacity but also the overall cost, transportation, and installation of the material. Understanding how to calculate this weight with precision can save significant time and resources.

Table of Contents

What are the I-Beam and H-Beam Sections?

I-Beams:

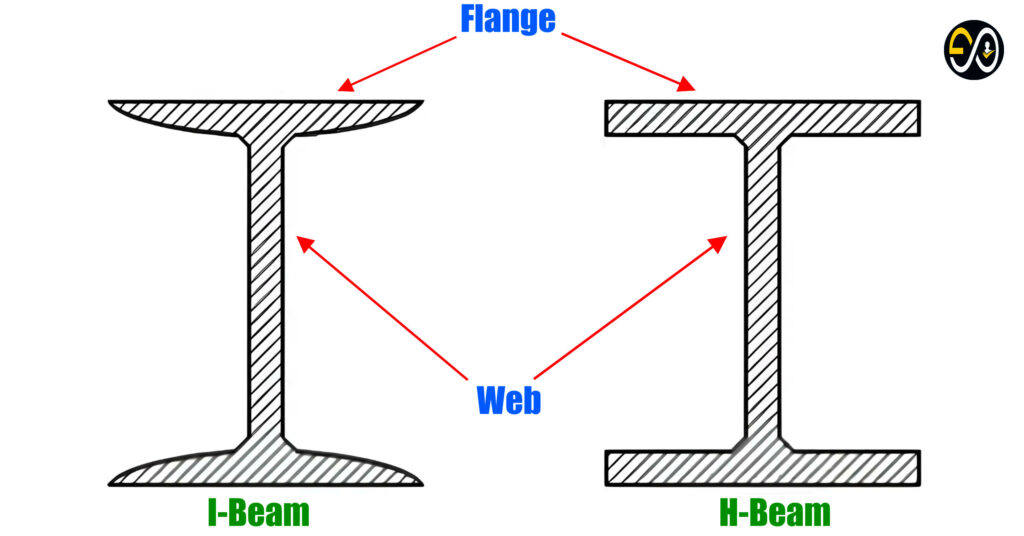

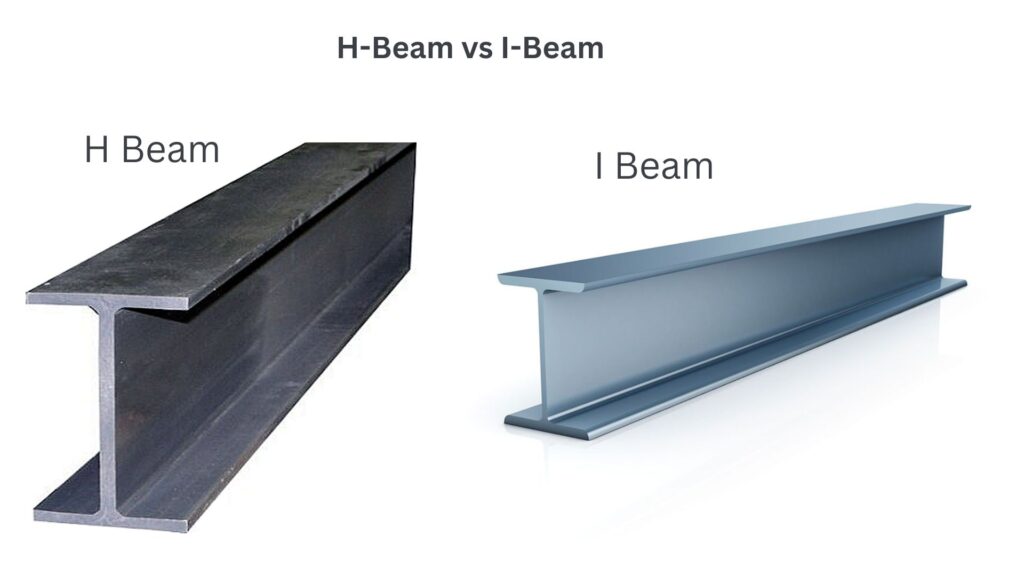

An I-beam is named after the shape of its cross-section, which resembles the letter ‘I’. The top and bottom flanges of an I-beam are narrower compared to the height of the vertical web. I-beams are commonly used for structural support in construction, providing strength to floors and roofs.

H-Beams:

On the other hand, an H-beam is similar to the I-beam but has wider flanges and a shorter vertical web, making it stronger and capable of bearing greater loads. Its wider surface area helps distribute weight more evenly, making it a preferred choice for heavy-duty structural applications.

Importance of Accurate Weight Calculation

The weight of a beam section directly affects its performance in various settings. For engineers and construction professionals, understanding the weight helps in:

- Structural Design: Ensuring the beam supports the required load without compromising safety.

- Cost Estimation: Calculating the exact weight helps in determining the cost of materials, transportation, and installation.

- Logistics and Handling: Beams must be moved and positioned carefully, and their weight is a key consideration in these processes.

Key Factors Influencing the Weight of I-Beam and H-Beam Sections

1. Material Density

The weight of a beam depends heavily on the density of the material used. Steel is the most common material for I-beam and H-beam sections, and its density is typically around 7850 kg/m³. Other materials, such as aluminum or stainless steel, have different densities and would need to be factored in accordingly.

2. Beam Dimensions

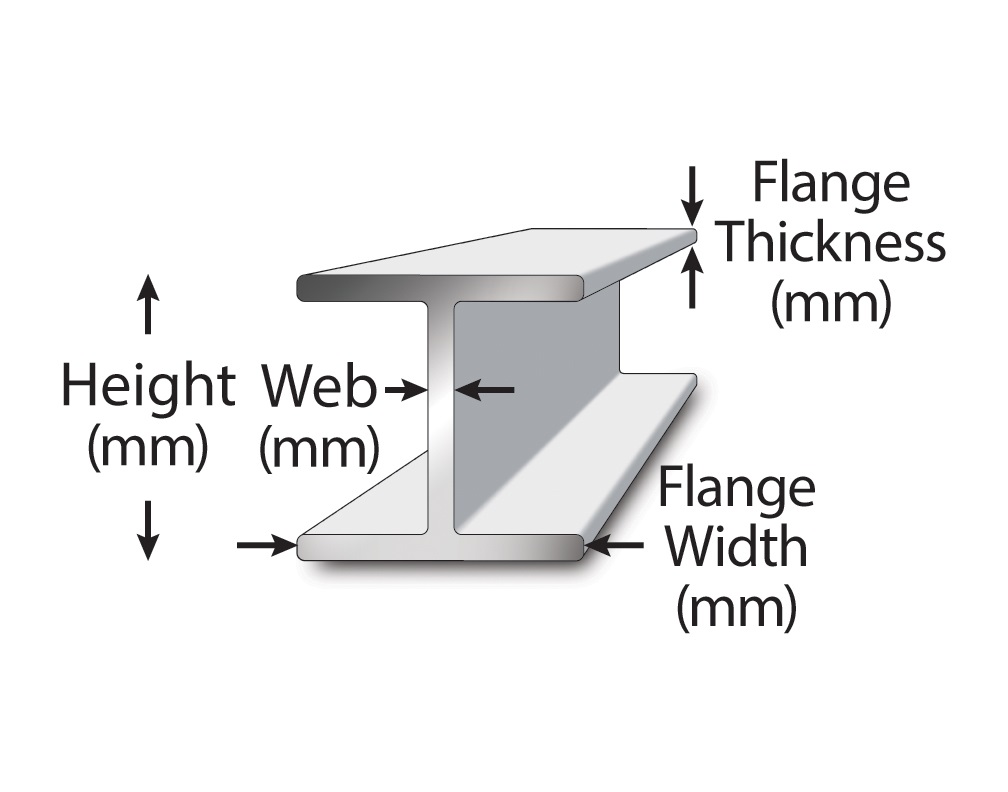

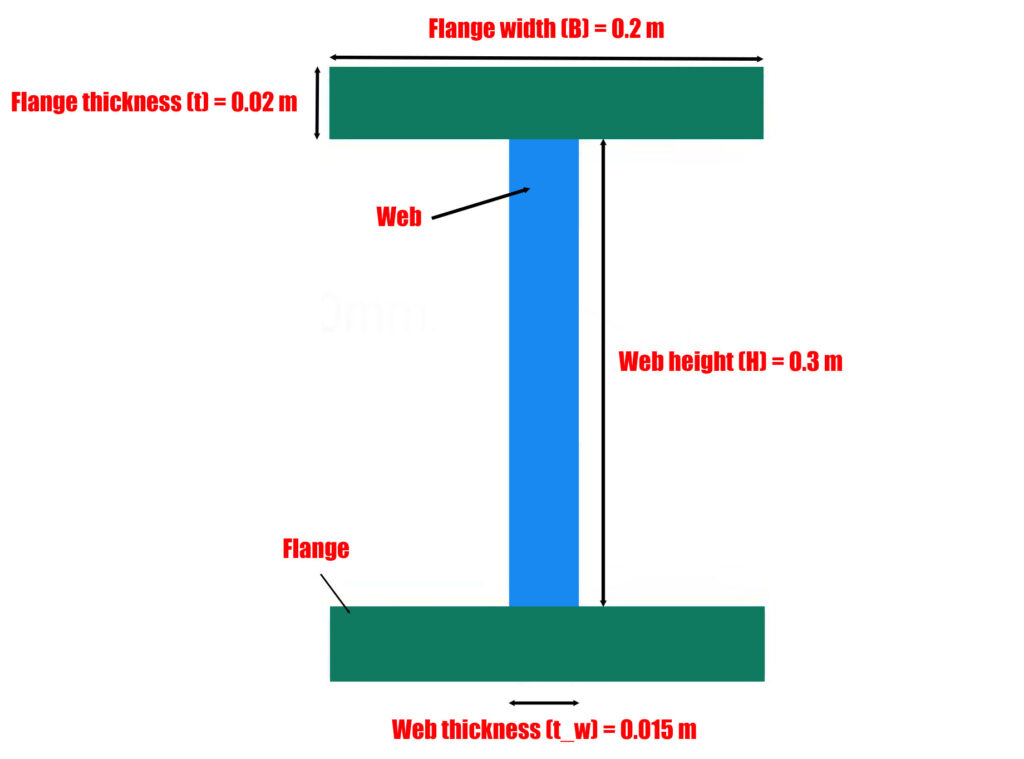

The cross-sectional dimensions of a beam play a pivotal role in its weight. These include:

- Flange width (B)

- Flange thickness (t)

- Web height (H)

- Web thickness (t_w)

3. Beam Length

While the cross-sectional dimensions determine the weight per unit length, the overall length of the beam is what ultimately defines the total weight of the section.

The formula for Calculating the Weight of I-Beam or H-Beam Sections

To calculate the weight of an I-beam or H-beam, you can use the following formula:

Weight (kg) = Cross-sectional area (A) × Length (L) × Density (ρ)

Where:

- A is the cross-sectional area of the beam, usually given in square meters (m2).

- L is the length of the beam, in meters (m).

- ρ is the density of the material, in kilograms per cubic meter (kg/m3).

Let’s break this down further.

Step-by-Step Calculation

1. Determine the Cross-Sectional Area (A)

The cross-sectional area of the beam is calculated by adding the areas of the flanges and the web.

For an I-beam or H-beam, the cross-sectional area formula is:

A = 2 × (Flange width × Flange thickness) + Web height × Web thickness

Where:

- Flange width (B) is the width of the flange.

- Flange thickness (t) is the thickness of the flange.

- Web height (H) is the height of the web between the two flanges.

- Web thickness (t_w) is the thickness of the web.

Example: Let’s say we have an I-beam with the following dimensions:

- Flange width (B) = 0.2 m

- Flange thickness (t) = 0.02 m

- Web height (H) = 0.3 m

- Web thickness (t_w) = 0.015 m

- Length = 6 m

Cross-Sectional Area (A) = 2 × (0.2 × 0.02) + 0.3 × 0.015

Cross-Sectional Area (A) = 2 × 0.004 + 0.0045 A = 0.008 + 0.0045 ⇨ 0.0125 m2

2. Calculate the Volume of the Beam

To calculate the volume of the beam section, multiply the cross-sectional area (A) by the length (L) of the beam.

Volume (V) = A × L = 0.0125 m2 × 6 m ⇨ 0.075 m3

3. Multiply by the Material Density

Finally, multiply the volume (V) by the material density (ρ) to get the total weight.

If we use steel as the material, with a density of 7850 kg/m3, the weight of the beam would be:

Weight = V × ρ ⇨ 0.075 m3 × 7850 kg/m3 ⇨ 588.75 kg

Thus, the total weight of this particular I-beam would be 588.75 kg.

Simplifying the Calculation Using Weight Per Unit Length

In many cases, manufacturers provide the weight per meter for standard I-beam or H-beam sections. If you know the weight per meter (W), calculating the total weight becomes a matter of simple multiplication:

Weight (kg) = Weight per meter (W) × Length (L)

For instance, if the beam’s weight per meter is 100 kg/m and its length is 6 meters, the total weight would be: Weight = 100 kg/m × 6 m ⇨ 600 kg

Using Tables and Software for Beam Weight Calculations

While manual calculations are a great way to understand the process, using weight tables or beam calculation software can simplify the task. These resources provide pre-calculated weights based on standard beam dimensions and materials, allowing you to quickly find the information you need without detailed calculations.

Steel manufacturers often publish detailed tables listing the weight per meter for different beam profiles and sizes. These tables are based on standard dimensions and are very useful for quick reference.

Notes:

- When the flange width is unequal, we have to calculate the area of the top and bottom flanges separately.

- The calculation procedure for all types of I-beam and H-beam (having sharp corners) will be the same as explained above.

Good Job