Ever bent a ruler to see how far it could go before it snapped? That playful moment perfectly demonstrates stress and strain, two fundamental concepts in physics and engineering. These terms may sound intimidating, but they’re quite intuitive once you get the hang of them. Let’s break down the difference between stress and strain in a way that makes sense to everyone.

Table of Contents

What is Stress?

In simple terms, stress is the internal resistance offered by a material when an external force is applied to it. Think of it as how much pressure the material feels due to the force.

Formula:

Stress (σ) = Force (F) / Area (A)

Units: Pascals (Pa) or N/m²

Everyday Examples of Stress

- Hanging a picture frame on a nail.

- A person standing on a diving board.

- Driving a car over a bridge.

All these situations involve forces acting on materials, generating stress.

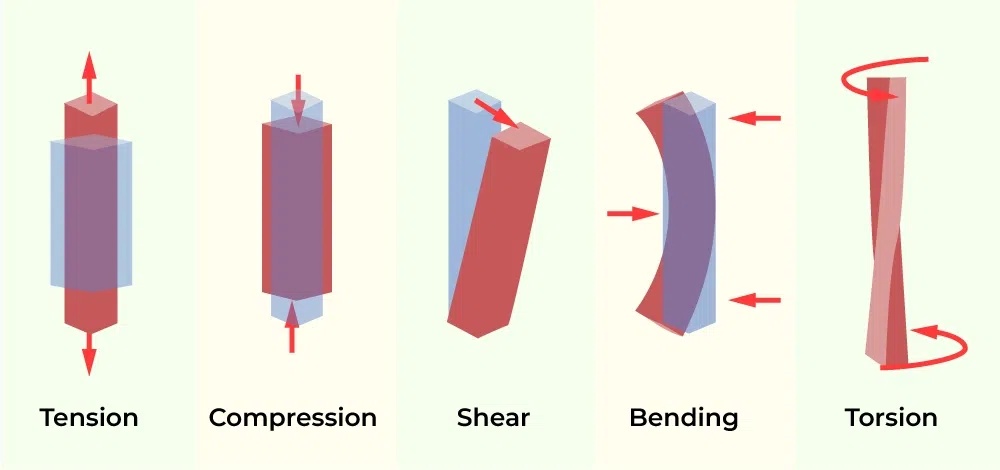

Types of Stress

- Tensile Stress – Pulling something apart (like stretching a rubber band).

- Compressive Stress – Squeezing or pushing inward (like pressing a sponge).

- Shear Stress – Forces applied parallel to a surface (like using scissors).

Internal Force and Area Relationship

Formula for Stress

As mentioned, stress = force divided by the area over which it is applied. So, smaller area = more stress for the same force. That’s why a needle can pierce skin so easily.

Importance of Cross-sectional Area

Imagine pressing your finger with a pen versus with the eraser end—the area makes all the difference.

What is Strain?

Strain is the measure of deformation—how much an object stretches or compresses under stress. It shows how a material responds after being pushed or pulled.

Formula:

Strain (ε) = Change in Length (ΔL) / Original Length (L₀)

Units: None (it’s a ratio)

How Strain Differs From Stress

- Stress is the cause.

- Strain is the effect.

Stress applies the pressure, and strain is how much the material bends, stretches, or compresses as a result.

Types of Strain

- Longitudinal Strain – Change in length.

- Lateral Strain – Change in width or diameter.

- Volumetric Strain – Change in volume.

Practical Examples of Strain

- Stretching a rubber band by twice its original length = strain of 1.

- Metal rod elongating under heavy weight.

Key Differences Between Stress and Strain

| Feature | Stress | Strain |

|---|---|---|

| Definition | Force per unit area | Deformation per unit length |

| Cause or Effect | Cause | Effect |

| Units | Pascals (Pa) | No units |

| Formula | σ = F/A | ε = ΔL/L₀ |

| Nature | External/Internal force | Response to that force |

Hooke’s Law and the Stress-Strain Relationship

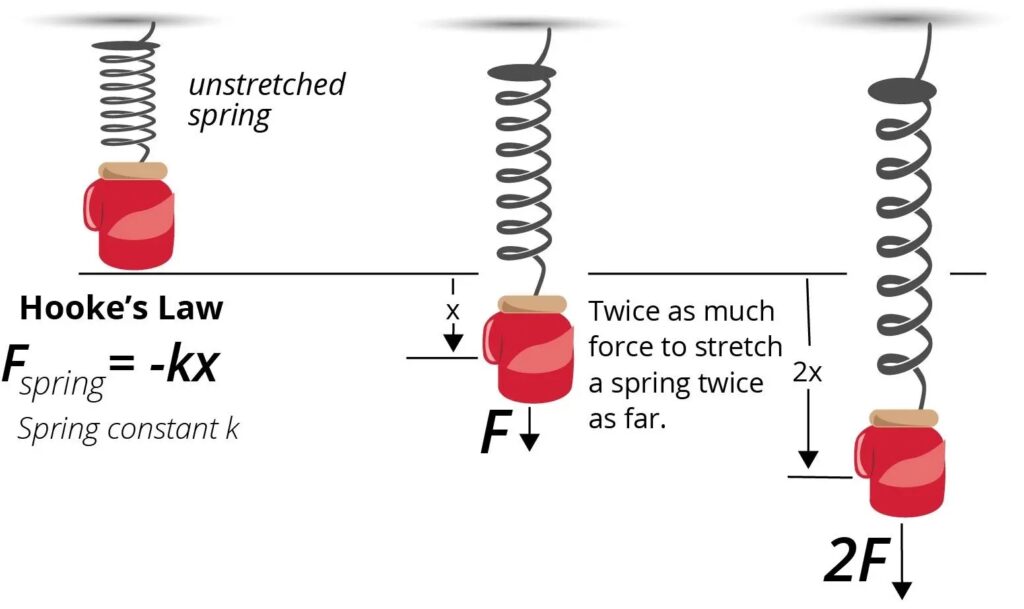

Introduction to Hooke’s Law

Hooke’s Law beautifully links stress and strain:

Hooke’s Law:

Stress ∝ Strain (within the elastic limit)

or

σ = E × ε

Where E is the Young’s Modulus (a material-specific constant).

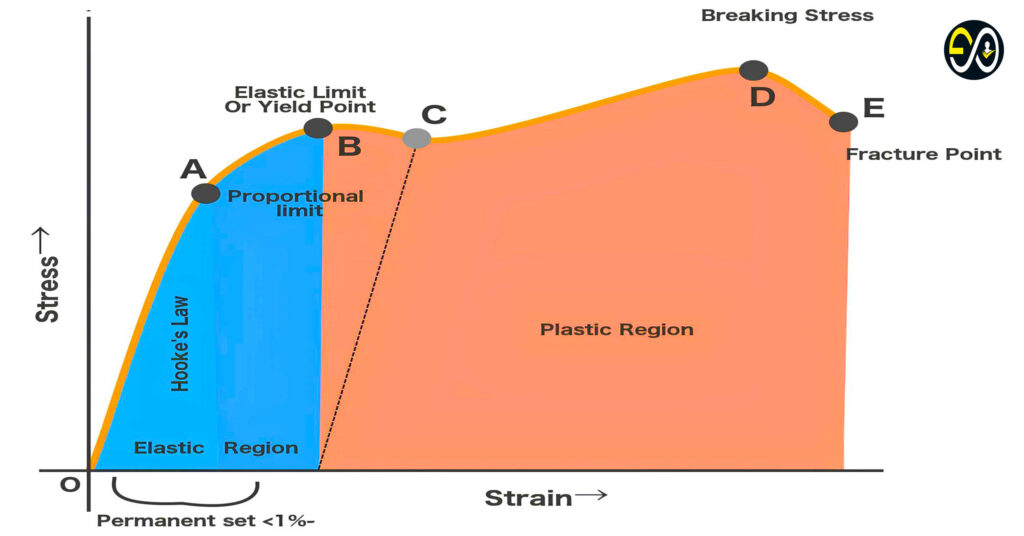

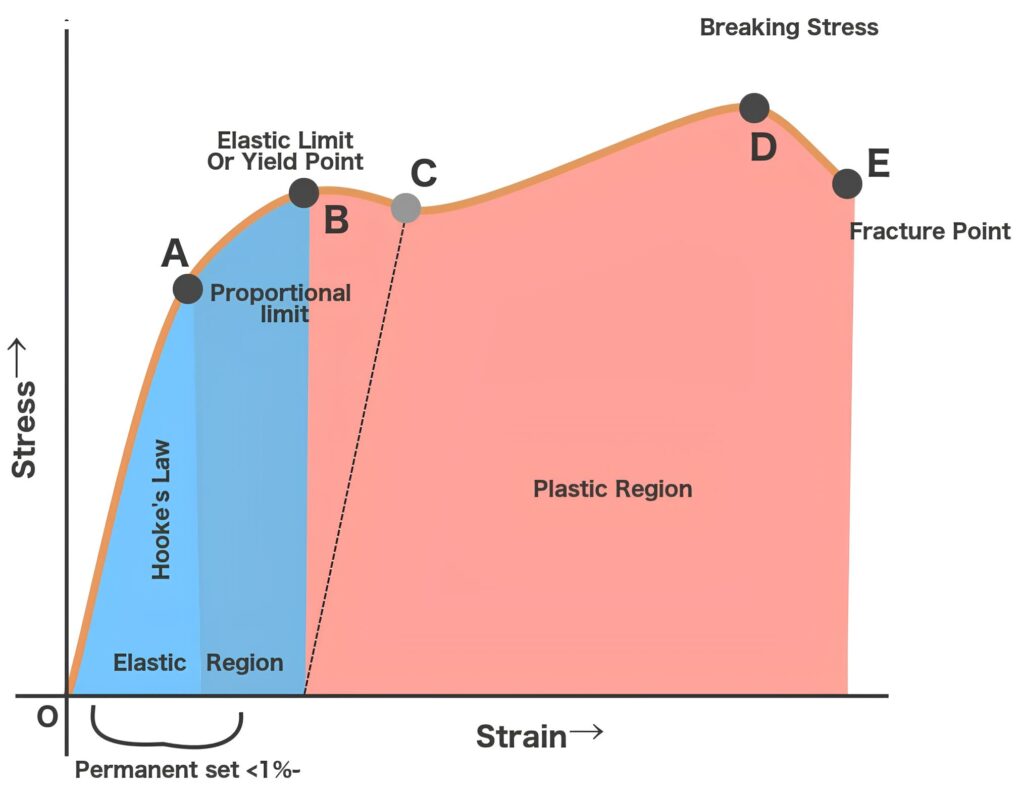

Stress-Strain Curve Explanation

This curve shows how a material behaves when stress is gradually increased.

Elastic Limit and Yield Point

- Elastic Limit: The Point beyond which a material returns to its original shape.

- Yield Point: Beyond this, the material permanently deforms.

Think of it as the difference between a rubber band snapping back and taffy stretching for good.

Stress-Strain Curve

The graph shows:

- Proportional Limit – Linear relation.

- Elastic Region – Material returns to shape.

- Yield Point – Permanent deformation starts.

- Ultimate Strength – Max stress before break.

- Fracture Point – Material breaks.

Real-World Interpretation

- Engineers use this to decide whether a material can be used in construction.

- Avoiding failure starts with reading the curve right.

Applications in Engineering

Why It Matters

Every bridge, aeroplane, or skyscraper you see stands because engineers calculated stress and strain precisely.

Structural Integrity and Design

Stress and strain determine how much load a structure can bear before bending or breaking.

Bridges, Buildings, and Machines

From the Eiffel Tower to your bicycle, ignoring stress and strain can be catastrophic. Designs are tested using these principles to ensure safety and performance.

Factors Affecting Stress and Strain

- Material Type – Steel vs. plastic.

- Temperature – Heat can weaken or soften materials.

- Type of Load – Static (constant) or dynamic (changing).

Common Misconceptions

- Stress and strain are not the same.

- Strain doesn’t have units—not a mistake, it’s a ratio.

- Not all materials follow Hooke’s Law (like rubber).

Summary of Differences

In short:

- Stress: Pressure applied.

- Strain: Resulting deformation.

- Measured differently.

- Represent cause and effect respectively.

Understanding these basics helps you grasp more advanced concepts in mechanics and materials science.