Introduction

Ever heard the term “floating slab” and wondered what it actually means? You’re not alone. This type of foundation is growing in popularity, especially for smaller buildings like garages, sheds, and some residential homes. But is it right for your project? Let’s dig into the nitty-gritty — from benefits and drawbacks to how it’s actually built.

Table of Contents

Understanding the Concept of Floating Slab

Definition and Purpose

A floating slab is a type of concrete foundation that “floats” over the ground without being anchored to deep footings. It’s essentially a concrete pad that rests on a bed of compacted gravel or sand. Unlike other foundation types, it doesn’t rely on below-ground walls or footings.

Where is it Used?

You’ll often find floating slabs under:

- Garages

- Workshops

- Sheds

- Seasonal homes

- Factories or light industrial buildings

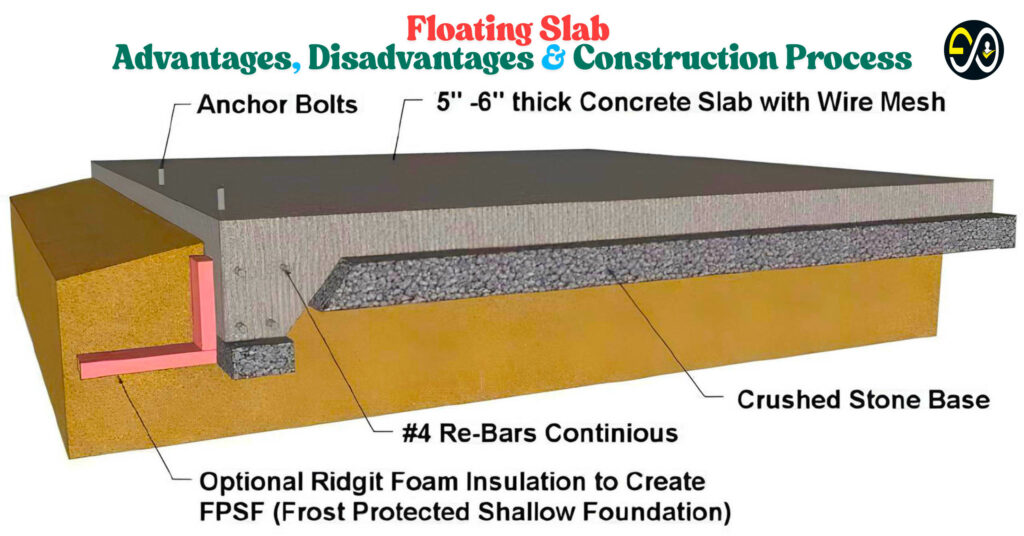

Components of a Floating Slab

Base Layer

The base is typically made of gravel or crushed stone. This layer ensures proper drainage and prevents moisture from getting trapped under the slab.

Reinforcement

Steel bars or mesh reinforcement help prevent cracking and increase the structural integrity of the slab.

Concrete Pouring

A strong, high-quality concrete mix is poured over the base and reinforcement to form the slab.

How a Floating Slab Differs from Other Foundations

Floating Slab vs Monolithic Slab

A monolithic slab is poured all at once, including the footings. A floating slab is poured separately and doesn’t include deep footings.

Floating Slab vs Traditional Foundation

Traditional foundations require extensive excavation and vertical walls, whereas floating slabs sit directly on the ground.

Advantages of Floating Slabs

Cost-Effectiveness

Floating slabs are significantly cheaper to build. No need for deep digging or extensive formwork.

Easy Installation

Simple process with fewer steps makes it faster to construct, which saves time and labor costs.

Minimizes Frost Heave

Because they aren’t anchored deep in the ground, floating slabs can move slightly with freezing and thawing cycles — reducing the risk of cracking.

Versatility in Application

Perfect for smaller, detached structures like garages, barns, and cabins.

Reduced Excavation Work

You won’t need large machinery or deep trenching. That’s a big win for DIY builders.

Disadvantages of Floating Slabs

Limited Load-Bearing Capacity

They’re not great for supporting very heavy structures like multi-story buildings.

Not Suitable for High-Rise Buildings

Floating slabs lack the deep anchorage required to stabilize tall buildings.

Potential for Cracks

Improper reinforcement or poor curing can result in cracks over time.

Moisture Seepage Risks

Without a good vapor barrier, moisture can seep up through the slab.

When Should You Use a Floating Slab?

Ideal Scenarios

- Detached garages

- Workshops

- Small houses or vacation cabins

- Structures in areas with a high water table

Unsuitable Conditions

- Steep slopes

- Poor soil stability

- Projects requiring basements or deep foundations

Floating Slab Construction Process

Step 1: Site Preparation

Clear the land, remove debris, and level the area.

Step 2: Formwork Setup

Build wooden forms around the perimeter to shape the slab.

Step 3: Placing Gravel or Crushed Stone Base

Lay and compact a 4-6 inch base layer to ensure drainage and support.

Step 4: Laying Reinforcement

Install steel mesh or rebar in a grid pattern across the formwork.

Step 5: Concrete Pouring and Finishing

Pour the concrete evenly, level it, and smooth the surface with a trowel.

Step 6: Curing Process

Allow the slab to cure for at least 7 days, keeping it moist to prevent cracks.

Materials Used in Floating Slab Construction

Concrete Mix

Usually a mix of Portland cement, sand, gravel, and water.

Reinforcement Bars

Steel bars (rebar) add strength and prevent cracking.

Insulation Materials

In colder climates, foam insulation may be added beneath the slab to prevent frost penetration.

Cost Considerations

Factors Affecting Cost

- Site location

- Slab thickness

- Materials used

- Labor charges

Budgeting Tips

- Get multiple quotes

- DIY parts of the process if possible

- Use local materials to cut transportation costs

Maintenance and Lifespan

Maintenance Practices

- Seal cracks early

- Keep drainage systems clear

- Apply concrete sealers every few years

Lifespan Expectations

With proper care, a floating slab can last 30–50 years or more.

Environmental Impact

Energy Efficiency

Slabs can be insulated to improve energy retention in buildings.

Waste Reduction

Less excavation means reduced environmental disruption and waste.

Common Mistakes to Avoid

Poor Ground Compaction

Loose soil can lead to settling and uneven surfaces.

Skipping Vapor Barrier

Always install a vapor barrier to avoid moisture problems.

Inadequate Reinforcement

Don’t cut corners on steel reinforcement — it’s essential for durability.

Expert Tips for Better Results

Hire Qualified Contractors

They’ll know local building codes and best practices.

Use Quality Materials

Skimping on materials can cost you more in repairs later.

Follow Local Building Codes

Avoid legal issues and ensure safety by adhering to local rules.