Introduction to Post-Tensioning in Bridge Construction

Since the 1940s, post-tensioning has been a pivotal advancement in civil engineering, particularly in constructing concrete bridges. This sophisticated method has transformed how we design and build structures, providing increased strength, reduced material usage, and the ability to support longer spans without sacrificing durability. Post-tensioning allows bridges to withstand the pressures of modern-day traffic loads, extreme weather conditions, and time effects.

What is Post-Tensioning in Bridges?

Post-tensioning is a type of prestressing technique that involves embedding high-strength steel tendons within the concrete. Once the concrete hardens, these tendons are tensioned to create compressive forces in the structure. This process counteracts tensile stresses under external loads, significantly reducing cracking and deformation.

In contrast to traditional reinforcement techniques, where steel rebar is simply placed within the concrete to bear tensile forces, post-tensioning allows for precise control over the level of stress in the concrete, leading to longer-lasting structures. This is especially critical for bridge construction, where reducing cracking and maintaining structural integrity over time is essential for public safety.

Benefits of Post-Tensioning in Bridges

The implementation of post-tensioning in bridge design offers a multitude of advantages, making it the preferred choice for many large-scale infrastructure projects. These benefits include:

- Increased Load Capacity: Post-tensioned bridges can support heavier loads compared to traditional reinforced concrete structures. This makes them ideal for modern roadways, where traffic volume and vehicle weight continue to grow.

- Longer Spans: With post-tensioning, bridge spans can be much longer, reducing the need for intermediate supports. This leads to fewer piers and a more aesthetically pleasing structure.

- Reduced Material Usage: By distributing forces more efficiently within the structure, post-tensioning minimizes the amount of concrete and steel required, leading to cost savings and a more sustainable design.

- Improved Crack Control: The compressive forces generated by post-tensioning counteract tensile stresses, which significantly reduces the risk of cracks developing in the concrete. This enhances the durability and longevity of the bridge.

- Reduced Maintenance: Because post-tensioned bridges are less prone to cracking and other forms of wear, they require less frequent maintenance, saving time and money over the structure’s lifetime.

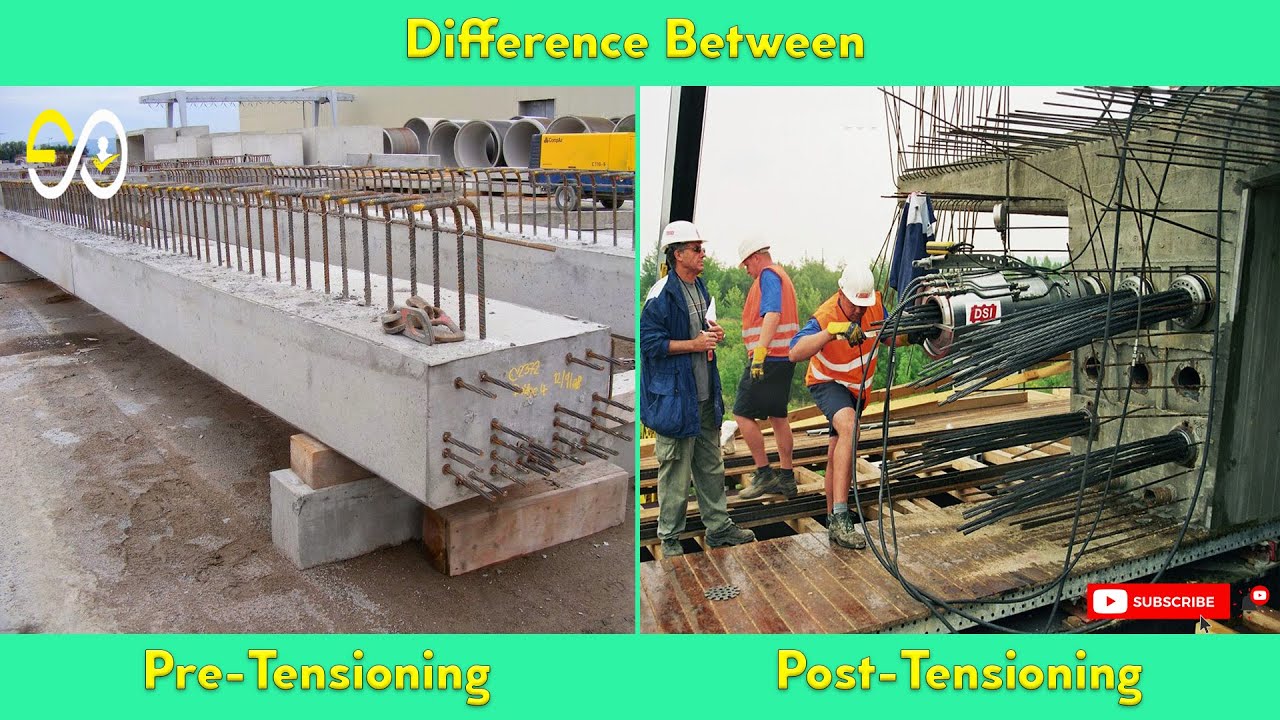

Post-Tensioning vs. Pre-Tensioning: Understanding the Differences

While both post-tensioning and pre-tensioning are forms of prestressing, they differ in the timing of the application of stress to the steel tendons. In pre-tensioning, the tendons are tensioned before the concrete is poured. Once the concrete sets, the tendons are released, transferring the stress to the concrete. Post-tensioning, on the other hand, occurs after the concrete has been poured and cured, allowing for more control over the stress distribution.

For bridges, post-tensioning is often preferred due to the flexibility it provides in construction. It is easier to apply post-tensioning forces after the concrete has been set, and this method is particularly well-suited for large spans, curved bridges, and complex geometries.

Applications of Post-Tensioning in Bridge Construction

The versatility of post-tensioning makes it applicable to a wide range of structural projects, beyond just bridges. Some common applications include:

- On-Ground Slabs: In addition to bridges, post-tensioning is often used in large slabs on the ground, such as those found in industrial facilities or commercial buildings, where large spans and load-bearing capacities are required.

- Seismic Retrofit: Post-tensioning is frequently used to strengthen existing structures, particularly in areas prone to seismic activity. By enhancing the structural integrity, it helps to prevent collapse during an earthquake.

- Water Storage Tanks: Concrete tanks used for storing water are often post-tensioned to ensure their long-term performance. This method prevents leakage and extends the lifespan of the tank.

- Masonry Walls: Post-tensioning can also be applied to masonry walls, increasing their resistance to external forces and reducing the need for excessive material.

Choosing the Right Post-Tensioning Specialist

When embarking on a bridge construction or repair project that involves post-tensioning, it is critical to select a qualified specialist. The complexity of post-tensioning systems requires not only the right materials but also a high level of expertise in design and installation.

A qualified specialist should adhere to industry-standard practices, ensuring that the materials and techniques used meet regulatory requirements. Proper quality control and inspection procedures should also be in place to guarantee that the post-tensioning system will perform as intended over the bridge’s lifetime.

Top Post-Tensioning Systems for Bridges

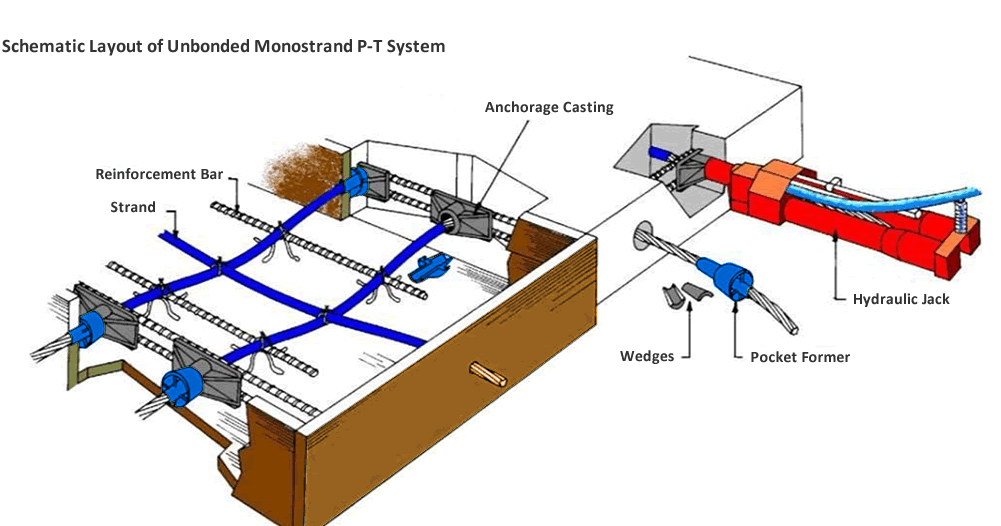

Leading providers of post-tensioning solutions offer a variety of systems to meet the needs of different projects. Some of the most commonly used systems include:

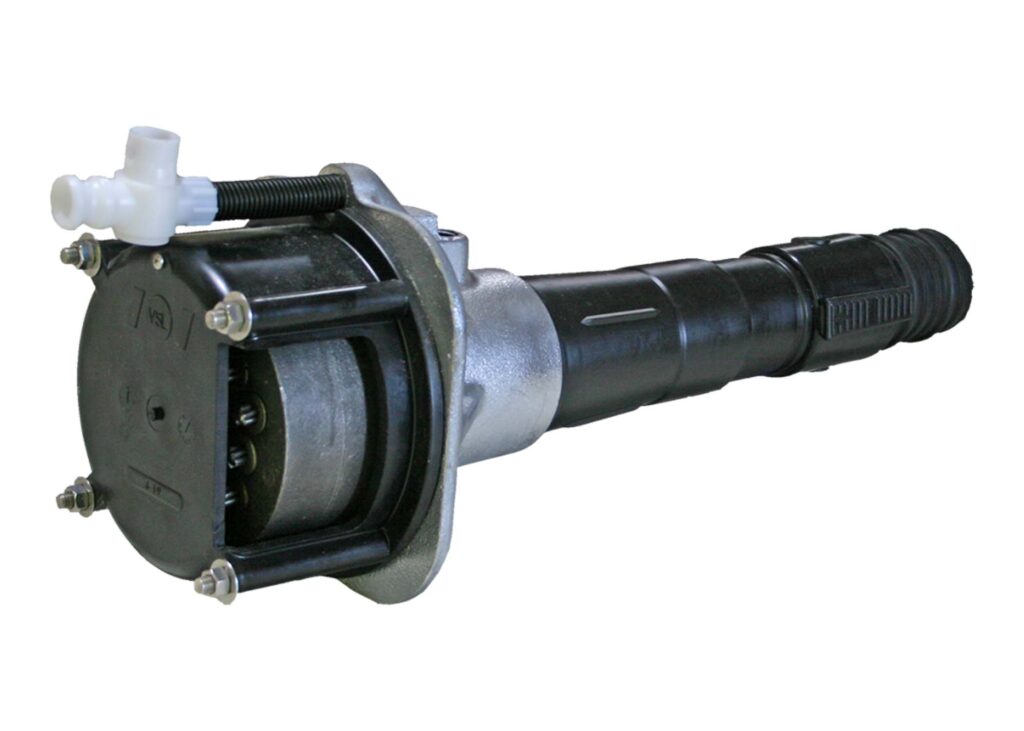

- Unbonded Monostrand Systems: These are ideal for bridges where flexibility and corrosion resistance are important. Each strand is coated with a layer of grease and encased in plastic to prevent corrosion, which is particularly useful in harsh environmental conditions.

- Bonded Multistrand Systems: This system is often used in bridges with large spans. The strands are placed in ducts and then grouted to create a solid bond between the strands and the concrete. This enhances the overall stability of the structure and provides superior long-term performance.

- Bonded Slab Post-Tensioning Systems: These are designed for flat or mildly sloping bridges. The system allows for the construction of thinner and more efficient slabs, reducing the overall weight of the bridge.

- VStrand™ Heat Resistant Tendons: For bridges exposed to high temperatures, such as those in industrial areas, heat-resistant tendons ensure the structure maintains its integrity under extreme conditions.

- Threaded Bars: These are often used in applications where post-tensioning is required to repair or retrofit existing bridges. The threaded design allows for precise tensioning, making it easier to adjust the system after installation.