Regarding earthquake-resistant design, every structure detail is pivotal in ensuring safety and minimizing damage. Among these crucial details are the seismic hooks or stirrups used in reinforced concrete structures. Seismic hooks, often overlooked, play a significant role in enhancing the resilience of buildings and infrastructure during seismic activities. In this article, we will explore why the 135-degree seismic hook is superior to the traditional 90-degree hook, particularly in high-seismic zones.

Table of Contents

What Are Seismic Hooks and Stirrups?

Seismic hooks, also referred to as stirrups or ties, are reinforcement elements used in reinforced concrete beams, columns, and other load-bearing members. These hooks provide shear reinforcement and ensure that the concrete remains intact, especially during lateral movements induced by earthquakes.

In reinforced concrete, steel bars are embedded in concrete structures to improve their tensile strength. The seismic hooks are used to tie these rebars (reinforcement bars) together, ensuring the confinement of concrete in regions prone to high stress. Stirrups typically form a loop around the main longitudinal reinforcement and are bent at the ends to form hooks that grip the structure tightly.

Why 135 Degrees? The Superiority of the 135-Degree Hook

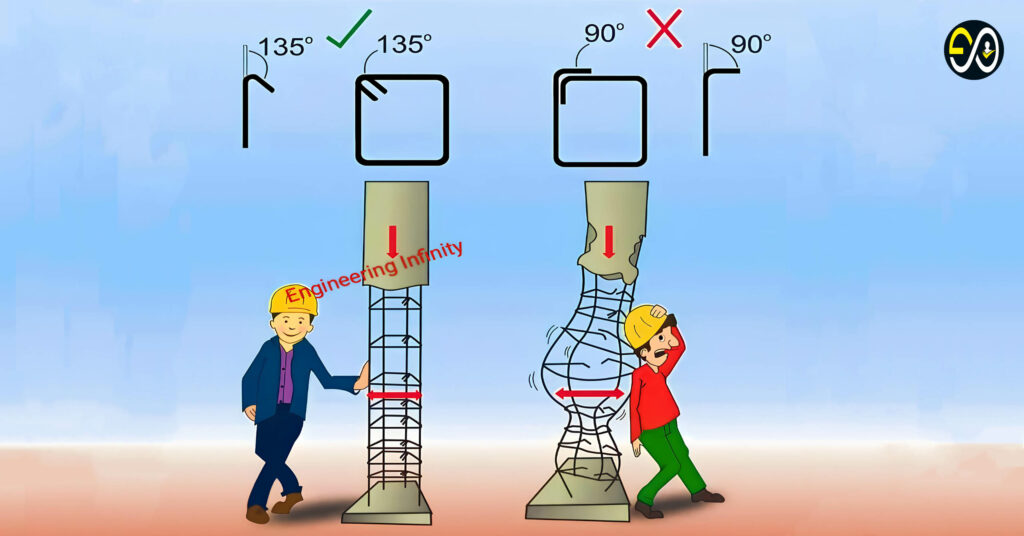

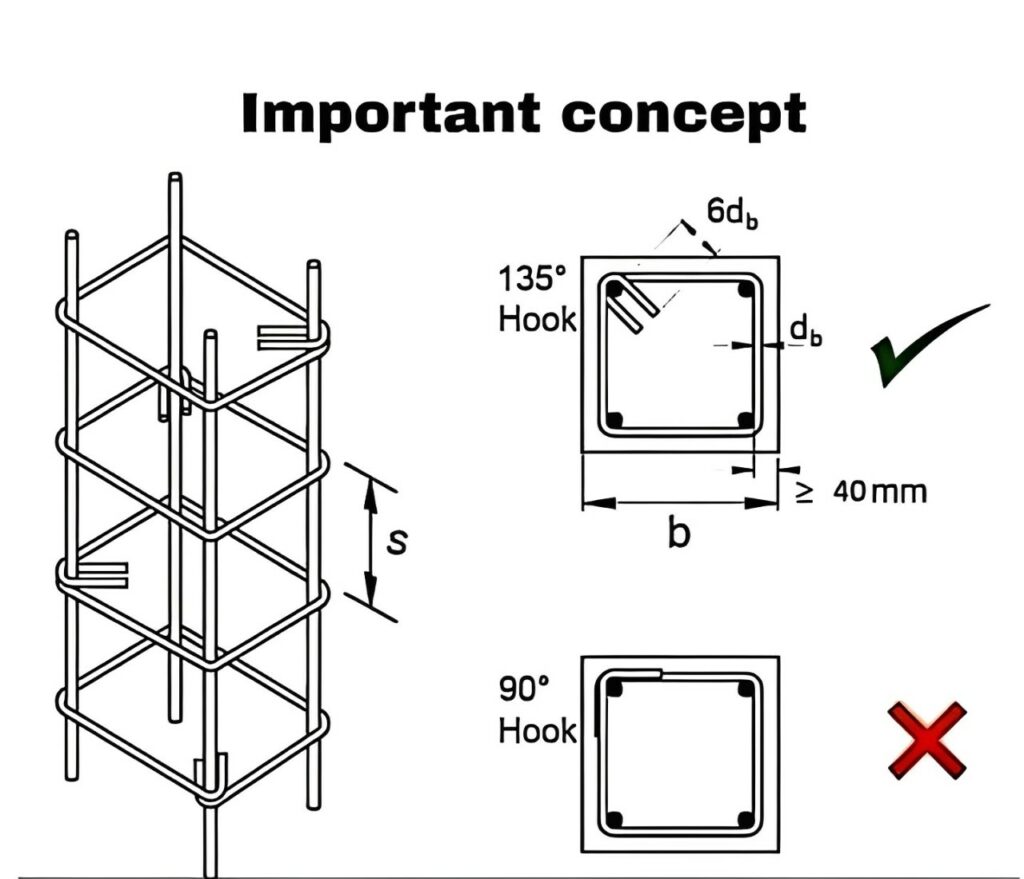

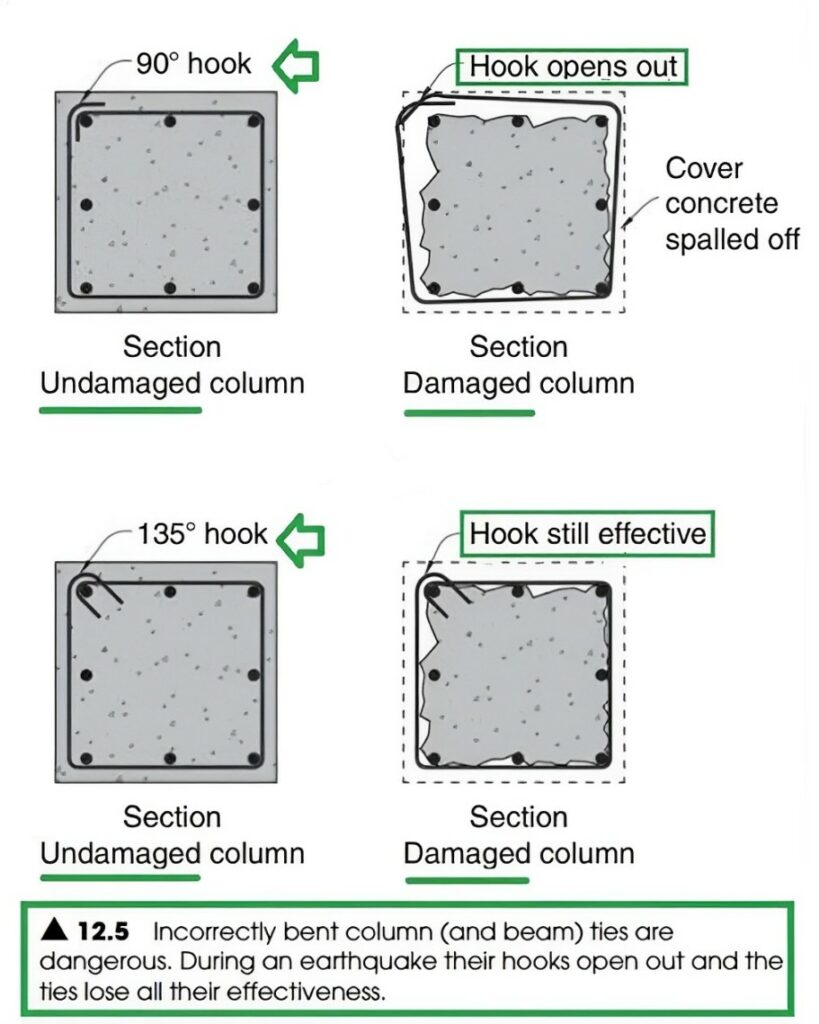

A key distinction in structural design is the angle at which these hooks are bent. The 135-degree hook has become the standard in modern seismic design codes, replacing the traditional 90-degree hook in most earthquake-prone regions. But why is this shift important?

Better Anchorage and Securement

The 135-degree hook offers superior anchorage compared to the 90-degree hook. This is because the angle of the bend creates a much tighter grip on the concrete and the surrounding steel reinforcement, preventing slippage during intense seismic events. The additional angle ensures the hooks stay embedded within the concrete, providing greater resistance to the dynamic forces experienced during an earthquake.

In contrast, the 90-degree hook, while once widely used, is prone to slippage and failure under seismic loading. The lack of sufficient anchorage in the 90-degree bend can lead to the early spalling (cracking and breaking) of concrete, which weakens the structure considerably during an earthquake.

Increased Confinement of Concrete

One of the primary purposes of seismic stirrups is to confine the core concrete within a structure, especially in columns. Proper confinement ensures that the compressive strength of the concrete is maintained under both normal and extreme loading conditions.

The 135-degree hook wraps more securely around the longitudinal reinforcement bars, effectively enclosing the concrete core. This additional confinement helps to prevent the buckling of longitudinal reinforcement, a common failure mode during seismic events. By contrast, the 90-degree hook does not offer the same level of confinement, leaving the concrete more vulnerable to degradation under stress.

Enhanced Ductility and Energy Dissipation

Ductility refers to the ability of a structure to deform under stress without breaking or collapsing. In earthquake engineering, high ductility is critical because it allows a structure to absorb and dissipate seismic energy over time, rather than transferring it directly to the building, which could lead to sudden failure.

The 135-degree seismic hook improves the overall ductility of the structure. It prevents premature failure by ensuring the reinforcement bars and concrete work together effectively, even under intense shaking. The improved anchorage of the 135-degree hook ensures that the stirrups remain engaged throughout the earthquake, providing vital support to the structural members.

The 90-degree hook, on the other hand, lacks the same ability to prevent sudden failure. In areas with high seismic activity, using 90-degree hooks can lead to a brittle response in structural elements, causing catastrophic collapse during severe earthquakes.

Comparison Between 135-degree and 90-degree Hooks

Let’s break down the differences between the two designs:

| 35-Degree Hook | 90-Degree Hook |

|---|---|

| Offers superior anchorage, reducing the risk of slippage. | Prone to slippage under seismic loading. |

| Provides better concrete confinement, preventing buckling of reinforcement bars. | Less effective in confining concrete, increasing the risk of failure. |

| Enhances ductility and energy dissipation during seismic events. | Leads to more brittle failure modes under stress. |

| Standard in modern seismic design codes. | Used in older designs, but now largely replaced in earthquake-prone areas. |

Modern Building Codes and Seismic Design

Most modern building codes, such as those established by the International Building Code (IBC) and the American Concrete Institute (ACI), now require the use of 135-degree seismic hooks in regions with high seismic activity. These codes have been developed based on extensive research and lessons learned from past earthquakes, where structural failures were often linked to poor confinement and inadequate hook design.

The ACI 318 Building Code, for example, mandates the use of 135-degree hooks in seismic zones, ensuring that structures have the required ductility and strength to withstand earthquakes. The code also specifies the size, spacing, and placement of stirrups to optimize structural performance under both normal and seismic conditions.